For years, our Heidelberg press has been the backbone of our printing operation—reliable, sturdy, and perfect for cranking out high-volume runs that keep our core business ticking. But lately, the market’s been shifting: clients want more flexibility, custom touches, and smaller batches than ever before. Adding a new Konica Minolta press isn’t about replacing the Heidelberg—it’s about filling gaps we couldn’t ignore. Honestly, three things made this decision a no-brainer: the surge in small-batch packaging requests, the surprisingly user-friendly user guides, and a streamlined install guide that kept downtime to a minimum.

Let’s be real—our Heidelberg is a workhorse for big jobs. Print 10,000+ boxes? It’s fast, consistent, and cost-effective. But over the past year, client after client was asking for runs of 500, 300, even 100 custom boxes: artisanal coffee brands testing new flavors, boutique skincare lines launching limited editions, local bakeries needing unique packaging for weddings. The Heidelberg just wasn’t built for that.

Switching dies, tweaking color profiles, and calibrating for tiny quantities took forever—setup alone could eat up half a day, and the waste (misprints, test runs) made small orders barely profitable. It was frustrating for us and for clients who needed quick turnarounds. The Konica Minolta, though? It’s designed for this exact scenario. Quick-change parts cut setup time by 40%, and it holds color perfectly even for batches as small as 100 units. We recently knocked out 300 hand-drawn chocolate boxes in 8 hours—something that would’ve taken 16 hours on the Heidelberg, with way less paper wasted. Finally, we can say “yes” to small-batch requests without eating into margins.

A press is only useful if your team can operate it—and let’s talk about the Heidelberg’s user manual. It’s thick, technical, and filled with jargon that feels like it’s written for engineers, not printers. Training a new hire on the Heidelberg used to take 4–6 weeks; even experienced staff would flip through pages for 20 minutes just to troubleshoot a simple color glitch. During peak seasons, that delay meant missed deadlines or costly mistakes.

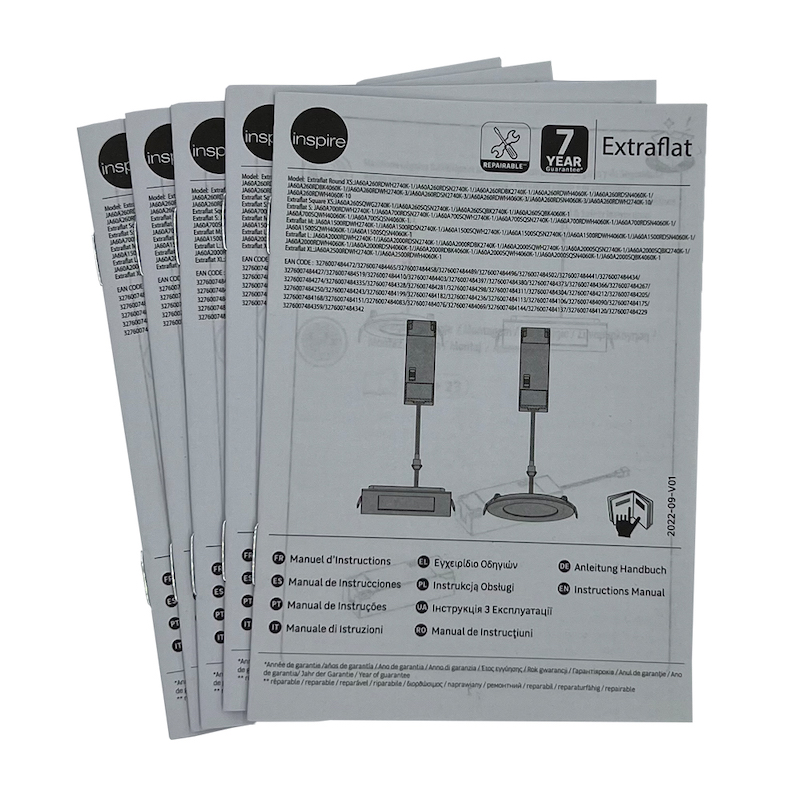

Konica Minolta’s user guide is a game-changer. It’s not a doorstop of text—there are step-by-step diagrams, links to short video tutorials (so you can watch instead of read), and simplified workflows for common tasks (like setting up small-batch packaging). New hires picked up basic functions in a week, and by week two, they were handling small-batch jobs on their own. The troubleshooting section even calls out issues specific to small runs—like color inconsistency in low-quantity prints—so we don’t waste time guessing. It’s refreshing to have a manual that’s designed for how we actually work, not how engineers think we should work.

We were dreading installing a new press—last time (with the Heidelberg), the install guide was vague at best. It didn’t specify exact floor space, power needs, or pre-installation prep. We ended up retrofitting the workshop mid-install, which delayed everything by 3 weeks and threw our production schedule into chaos. This time, we crossed our fingers for better—and Konica Minolta delivered.

Their install guide spelled out every detail: 30 square meters of floor space, 220V/30A power, even the exact type of compressed air connection we needed. It included a day-by-day timeline, so we could schedule installation during night shifts (when the Heidelberg wasn’t running) to avoid disruption. From uncrating to full calibration, the whole process took 5 days—no surprises, no last-minute fixes. The guide even had post-installation checklists to make sure the press was hitting quality standards. We were printing small-batch orders within a week of setup—something we never thought possible with a new machine.

Buying the Konica Minolta didn’t make our Heidelberg obsolete—it made our whole operation stronger. The Heidelberg still handles the big, high-volume jobs that keep our lights on, while the Konica Minolta crushes the small-batch packaging requests that were once a headache. Add in the intuitive user guide that cut training time in half and an install guide that actually respected our production schedule, and this wasn’t a “nice-to-have” purchase—it was a must.

Now, we can serve everyone: from major brands needing 50,000 boxes to local startups testing 200. That flexibility? It’s what keeps us ahead in a market where clients don’t just want prints—they want solutions tailored to their needs.