1. Green and Environmental Protection, Plastic Replacement

Green and environmentally friendly packaging is a high-tech form of packaging. From raw materials to packaging design and production, to packaging use and recycling, every link requires resource saving, high efficiency, environmental protection and harmlessness. Green and environmentally friendly packaging has received widespread attention from the international community. Its research should consider the whole process of development, design, production, use, recycling and disposal. At the same time, with the increasingly stringent national environmental protection policies and "plastic restriction" and "plastic replacement" policies, actively developing green and environmentally friendly packaging and plastic replacement packaging is becoming an important development trend in the industry. With the growing demand for sustainable solutions, xlhpackaging provides guarantees related to environmental responsibility: Xinlihong Paper guarantees that the paper used for packaging comes from responsibly managed forests or is made of recycled materials to ensure minimal impact on the environment. In order to support its environmental protection claims, Xinlihong Paper guarantees that the packaging boxes meet specific environmental certifications and have obtained FSC (Forest Management System Certification Certificate).

2. Production Automation And Intelligence

The advancement of technical level has gradually made the automation and intelligent application of printing and packaging production a reality. Advanced technologies such as digital printing, integrated packaging printing technology, and automated inspection technology are gradually being applied to all aspects of product production and quality management in the industry, further improving production efficiency, shortening production cycles, and saving labor costs. Traditional equipment with poor performance, low efficiency, and high energy consumption will be gradually replaced, and the application of automation and intelligent technology, integrated packaging printing technology, and digital printing will become the future development direction of printing and packaging industry technology.

3. Market Concentration Increases

In 2020, the sales revenue of the top five manufacturers in my country's paper packaging industry accounted for 13.01% of the total revenue of enterprises above designated size in the industry, which is 5.40% higher than the corresponding proportion of the top five manufacturers in 2016. The market concentration has further increased. Affected by the branding and concentration of downstream consumer industries, paper packaging manufacturers with customer resource advantages can seize the business growth opportunities brought by the increase in market concentration in the industry.

4. Upgrading The Comprehensive Service Capabilities Of Paper Product Manufacturers

With the rapid development of the economy and society, the downstream consumer industry has shown a trend of diversified demand and accelerated product iteration. As a packaging supporting industry for the downstream consumer industry, the stickiness of the paper packaging industry with downstream core customers will be further enhanced in the future. Paper product manufacturers will be upgraded from original product manufacturers to comprehensive service providers, and downstream customers will gradually upgrade their requirements for comprehensive service capabilities.

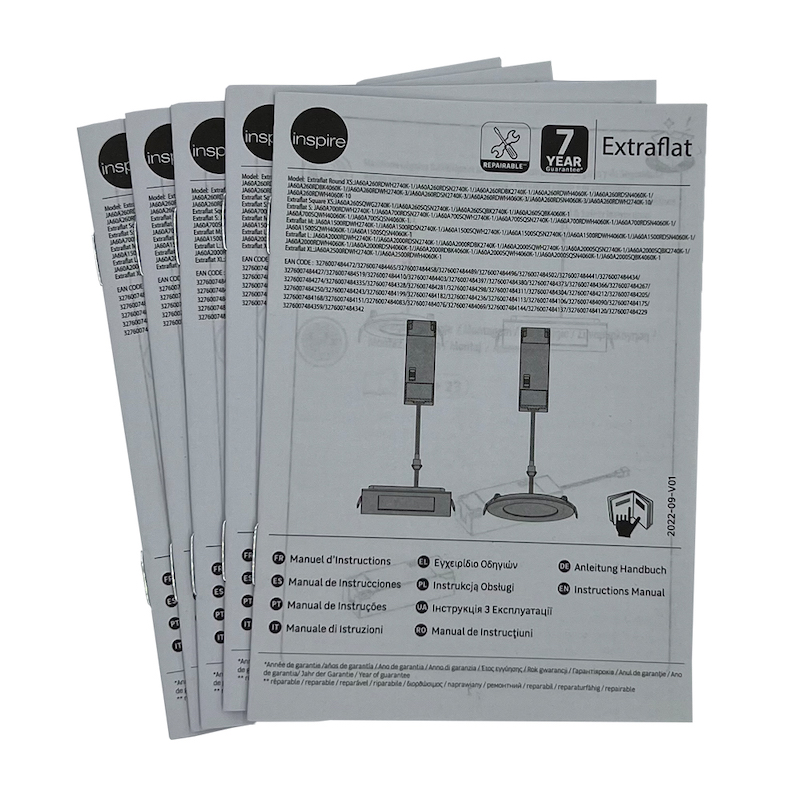

Xiamen Xinlihong Paper Co., Ltd. is a professional color printing manufacturer. As an experienced manufacturer, we are able to provide customers with professional printing and packaging OEM/ODM services, a one-stop solution from design to production, to meet customers' personalized needs for brands and products. Our main products are: corrugated boxes, card boxes, folding boxes, lid and base boxes, instruction manual, paper bags, envelope bags, gift boxes、food packaging boxes and other paper packaging.